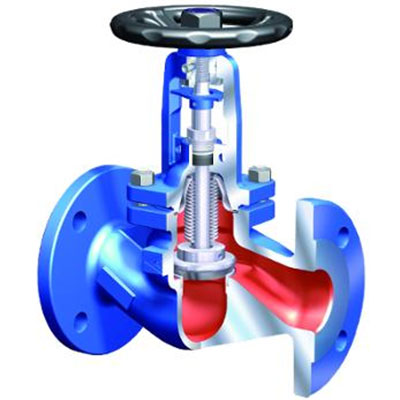

Advantages of Bellows Seal Globe Valve Compared With Ordinary Packing Gland Seal Globe Valve

Date:2019-10-15 Click:2113

As a pressure pipe component, the valve controls the connection and disconnection of the pipeline fluid. It is like a brake pad on a car. Once it is damaged, the consequences are unimaginable. Therefore, the service performance and service life of the valve directly affect the normal operation of the pipeline system. Once the valve is damaged, the system must be shut down for maintenance. The loss is not comparable to the cost of several valves, so the quality and life of the valve is particularly important.

The bellows stop valve is particularly outstanding in these two aspects. It has a double seal to ensure zero leakage, and it is a zero leakage standard for helium mass spectrometry detection, which is very safe and reliable. The number of bellows cycles can reach more than 10,000 cycles without damage, far exceeding the switch life of the ordinary shut-off valve packing seal several times. In addition, the bellows valve can prevent external dust from entering the valve body, ensuring the cleanliness of the medium. For example, under the conditions of high-purity silicon powder, pure oxygen, food, vacuum, etc., the performance of the bellows shut-off valve is very outstanding.

(product pictures come from the Internet)

Ordinary shut-off valve packing and valve stems have dynamic friction during the switching process, and the filler will be worn out and fail. Especially in the case of high temperature and low temperature, the filler will expand and contract, and the pre-tightening force of the filler will change to cause the packing seal to fail. At low temperatures, the filler is likely to freeze, and during the switching process, the filler is easily scratched by ice.

In summary, the advantages of bellows globe valves compared to conventional globe valves can be summarized as follows:

1. The bellows stop valve can meet the zero leakage standard of helium mass spectrometry detection, which is very safe and reliable.

2. The service life of the bellows cut-off valve is much higher than that of the ordinary stop valve. The packing of the ordinary stop valve is easy to be damaged and the replacement frequency is high.

3. Bellows Valve The valve stem seal has a metal barrier that can be used in high-demand conditions such as oxygen, which requires absolute isolation inside and outside the valve.

4. The bellows of the bellows stop valve has a telescopic function and is not affected by thermal expansion and contraction. It has obvious advantages for occasions where the medium temperature gradient is large.

5. The bellows valve has a double seal. When the bellows is intact, the filler is completely isolated from the medium, which protects the filler well and greatly prolongs the service life.